When Sarah Chen’s nearly-new stainless steel refrigerator started showing dark streaks and unusual corrosion after just eighteen months in her Strathcona home, she assumed it was a manufacturing defect. What she didn’t realize was that her kitchen appliances were under constant assault from an invisible enemy: container ship pollution from Vancouver’s massive port operations just blocks away. Like thousands of other Vancouver homeowners living within the port’s pollution zone, Sarah was about to discover a costly reality that appliance manufacturers don’t advertise and home insurance policies don’t cover.

Vancouver’s position as Canada’s largest port handling half the country’s trade outside North America creates a unique pollution cocktail that accelerates appliance deterioration far beyond normal coastal conditions. The concentrated heavy metals, sulfur compounds, and metallic particles released by container ships don’t just disappear into the atmosphere—they settle into homes, infiltrate appliances, and begin a slow but relentless process of corrosion that can cost the average homeowner over $1,200 in premature repairs and replacements.

Understanding this hidden threat is crucial for Vancouver residents, as traditional coastal protection strategies often fall short against the specific challenges posed by marine shipping emissions. The difference lies not just in intensity, but in the unique chemical composition of port pollution that targets appliance components in ways that standard salt air protection cannot address.

Key Takeaways

- Port pollution accelerates appliance corrosion 40% faster than general coastal conditions due to concentrated heavy metals and sulfur compounds from container ship emissions

- Container ship fuel combustion releases specific corrosive elements including vanadium, nickel, and sulfur dioxide that target appliance metal components differently than regular salt air

- The average Vancouver homeowner within 5km of port terminals faces $1,200 in premature appliance replacements and repairs directly linked to marine shipping pollution exposure

- Appliances in port-adjacent neighborhoods show 2-3 years shorter lifespans compared to inland Vancouver areas, with refrigerators and HVAC systems most severely affected

- Targeted protection strategies implemented before visible damage appears can reduce port pollution damage by up to 70% while extending appliance operational life significantly

How Port Pollution Differs from General Coastal Air Quality

While Vancouver’s entire metropolitan area experiences coastal conditions, the pollution environment near container terminals creates fundamentally different challenges for household appliances. Container ships historically burned high-sulfur residual fuel oil, creating emissions dramatically different from general ocean air. Research shows that large marine vessels released PM2.5 enriched with vanadium and nickel, which are specific markers of heavy fuel oil combustion, creating pollution signatures unlike anything found in typical coastal environments.

The concentration factor makes port pollution particularly devastating for appliances. Unlike diffuse coastal salt air that spreads evenly across broad areas, container ship emissions create concentrated pollution zones around terminals where particle density exceeds normal coastal conditions by several times. These concentrated zones extend approximately 5 kilometers inland, with the most severe effects occurring within 2 kilometers of active shipping berths.

Seasonal shipping patterns compound the problem by creating pollution surges during winter months when appliances already work hardest. Container traffic increases 30-40% during peak shipping season from October through March, coinciding precisely with when heating systems, refrigerators, and other appliances experience their greatest operational stress. This timing maximizes vulnerability, as appliances dealing with internal condensation and temperature fluctuations become more susceptible to pollution infiltration.

Wind patterns unique to Vancouver’s geography carry port emissions directly into residential neighborhoods like Strathcona, Mount Pleasant, and parts of East Vancouver. Air quality monitoring in Strathcona neighborhood consistently shows NO₂ concentrations exceeding Metro Vancouver objectives, demonstrating how port pollution creates persistent exposure levels that general coastal conditions simply don’t produce.

Temperature inversion events common to Vancouver’s coastal climate trap port pollution close to ground level, preventing normal atmospheric dispersion. During these events, which occur frequently during fall and winter months, pollution concentrations can spike 3-5 times normal levels, overwhelming even well-maintained appliance filtration systems and accelerating corrosion processes throughout affected neighborhoods.

The Science Behind Container Ship Emissions and Appliance Corrosion

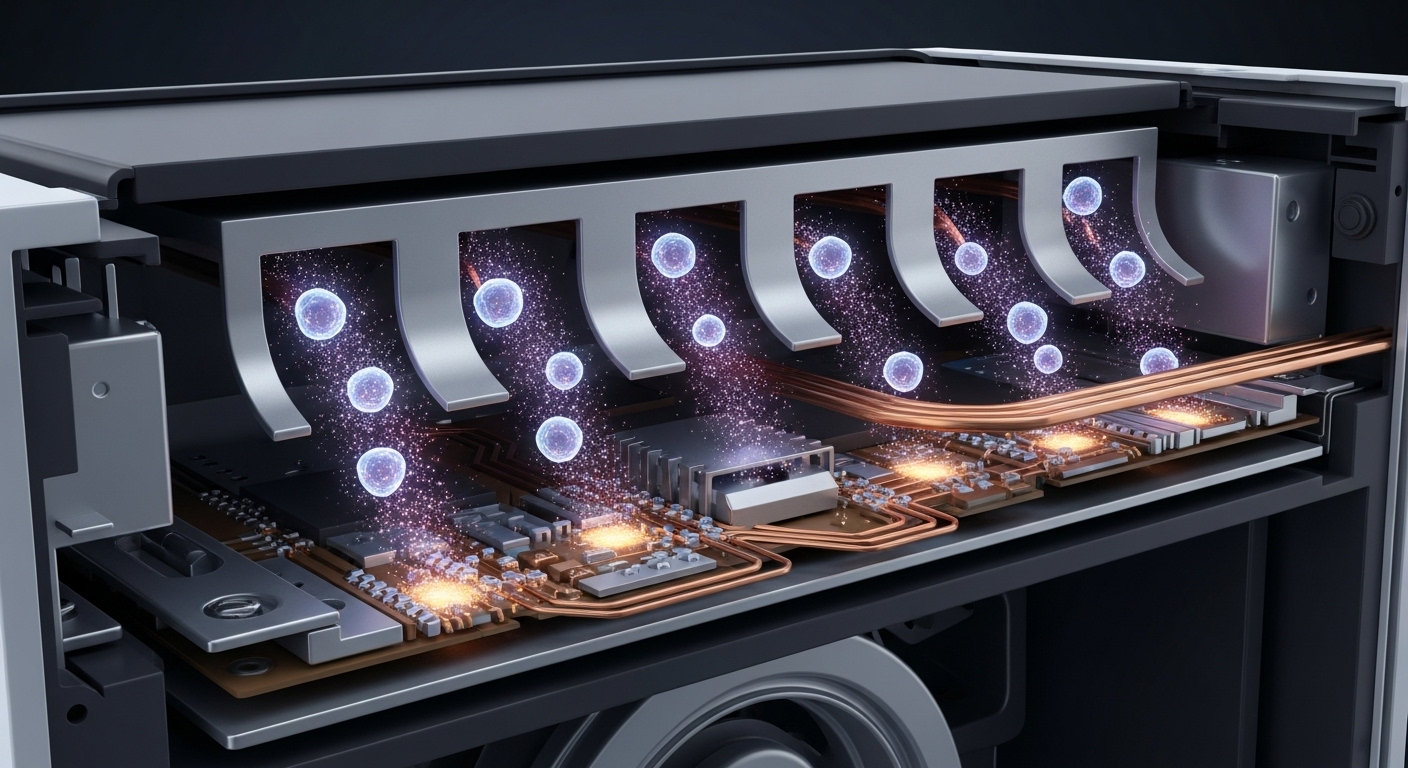

Container ship pollution attacks appliances through mechanisms that standard coastal protection strategies weren’t designed to handle. The fundamental difference lies in particle composition and behavior. While normal salt air creates surface corrosion that progresses gradually inward, port pollution contains microscopic metallic particles that penetrate deep into appliance systems through ventilation ports, creating internal corrosion cells that work from the inside out.

Heavy metal contamination from marine fuel combustion creates particularly aggressive corrosion environments. Before stricter fuel regulations, PM2.5 composition in port cities showed dramatic levels of sulfate and heavy metals nickel and vanadium, which form galvanic corrosion cells when they contact different metals within appliances. This galvanic corrosion accelerates deterioration rates far beyond simple oxidation, creating cascading failures as different metals within the same appliance corrode at different rates.

Sulfur dioxide emissions specifically target electronic components within modern appliances. Research indicates that sulfur dioxide is particularly aggressive toward copper contacts used in electronic equipment, causing connection failures, control board malfunctions, and sensor degradation that often appear as mysterious electronic failures rather than obvious corrosion damage.

The thermal cycling effects of container ship pollution create additional stress on appliance components. As pollution particles accumulate on heat exchangers, coils, and ventilation systems, they disrupt normal thermal management, forcing appliances to work harder and creating temperature fluctuations that stress seals, gaskets, and electronic components. This thermal stress compounds chemical corrosion effects, accelerating overall system degradation.

Humidity interaction with port pollution creates particularly destructive environments for appliances. Container ship emissions include hygroscopic particles that attract and hold moisture, creating persistent damp conditions on appliance surfaces even when ambient humidity appears normal. These micro-environments of trapped moisture and metallic particles provide ideal conditions for sustained corrosion processes that continue even during dry weather periods.

The $1,200 Reality: Breaking Down Hidden Appliance Damage Costs

The true cost of port pollution damage extends far beyond obvious repair bills, creating a cascade of expenses that most Vancouver homeowners never connect to their proximity to shipping activities. Understanding these costs requires examining both direct replacement expenses and the hidden additional charges that accompany major appliance failures in Vancouver’s challenging service environment.

Refrigerator replacement represents the largest single expense for most affected homeowners. When port pollution damages cooling coils, compressors, or electronic controls, repairs can cost $500-800 before identifying the problem, especially during emergency service calls, but total replacement costs often reach $1,800-2,500 when professional installation, delivery charges, and disposal fees are included. Port-adjacent neighborhoods face additional complications, as technicians often require specialized cleaning procedures for heavy metal contamination, adding $200-400 to standard service costs.

HVAC system damage creates particularly expensive scenarios because port pollution affects multiple components simultaneously. Evaporator coils, blower motors, and electronic controls all succumb to heavy metal corrosion, often creating cascading failures where repairing one component reveals additional damage. Emergency heating system failures during Vancouver’s winter months can result in service premiums exceeding $800 just for priority response, before actual repair work begins.

The timing of appliance failures in port areas creates additional financial pressure through compressed replacement schedules. Instead of normal 10-15 year appliance lifecycles, port pollution often forces replacements every 7-10 years, meaning homeowners face major appliance purchases more frequently while still paying for previous purchases. This compressed timeline eliminates the natural spreading of