Wondering why your expensive kitchen appliances keep breaking down despite regular use and proper care? Vancouver’s notorious rainy season creates a hidden threat that’s systematically destroying your home equipment – and most homeowners have no idea it’s happening until it’s too late. Picture this: it’s a typical Vancouver morning in February, rain drumming against your windows for the fifth consecutive day. You reach for your morning coffee, but your espresso machine sputters and dies. Later, you notice water pooling around your dishwasher, and by evening, your refrigerator is making that ominous grinding noise that signals expensive repairs ahead. What you’re experiencing isn’t bad luck or coincidence – it’s the direct result of Vancouver’s unique coastal climate systematically attacking your kitchen equipment in ways that most manufacturers never anticipate when designing their products.

The harsh reality is that Vancouver’s combination of persistent high humidity, salt-laden ocean air, and dramatic temperature fluctuations creates a perfect storm of conditions that can reduce appliance lifespans by decades. While other Canadian cities deal with predictable seasonal changes, Vancouver’s weather patterns subject your kitchen equipment to constant environmental stress that gradually compromises every component, from electronic control boards to mechanical seals and gaskets. The moisture that makes our region so lush and green is the same force that’s quietly infiltrating your appliances, promoting corrosion, encouraging mold growth, and creating electrical failures that often manifest as mysterious performance issues long before any visible damage becomes apparent.

Understanding these hidden threats represents the first step toward protecting your valuable kitchen investments. The financial implications extend far beyond simple repair costs, encompassing energy efficiency losses, premature replacement expenses, and potential property damage from water leaks and electrical failures. Research indicates that comprehensive moisture protection strategies can extend appliance lifespans by 3-5 years while dramatically reducing repair frequency and maintaining optimal performance throughout their service life.

This comprehensive analysis reveals not only how Pacific Northwest humidity systematically damages kitchen equipment but also provides actionable strategies for protection that can save thousands of dollars in repair and replacement costs. From understanding the science behind moisture infiltration to implementing professional-grade protection systems, homeowners who grasp these principles can successfully maintain reliable appliance operation despite Vancouver’s challenging environmental conditions.

Key Outtakes

- Vancouver’s coastal humidity accelerates appliance component corrosion and electronic failures at rates far exceeding manufacturer expectations

- Salt air penetration reaches surprisingly far inland, creating aggressive corrosion conditions that can reduce equipment lifespans by up to 40%

- Temperature fluctuations between seasons stress seals and gaskets through repeated expansion-contraction cycles

- Proper humidity control systems and targeted maintenance can extend appliance life by 3-5 years compared to unprotected units

- Professional moisture management represents a cost-effective investment compared to frequent repairs and premature replacements

Understanding Vancouver’s Unique Climate Challenges for Appliances

Vancouver’s coastal environment presents environmental stressors that distinguish it from virtually every other major Canadian metropolitan area. The city’s position between the Pacific Ocean and the Coast Mountains creates a microclimate where humidity levels remain consistently elevated throughout the year, often exceeding the optimal operating conditions recommended by appliance manufacturers. This persistent moisture doesn’t simply create surface condensation that can be wiped away; instead, it penetrates deep into the internal mechanisms of kitchen equipment, where it initiates a cascade of deterioration processes that gradually compromise performance and reliability.

The scientific principles behind humidity-induced appliance damage involve multiple interconnected mechanisms that work synergistically to accelerate wear patterns. When warm, moisture-laden air encounters the cooler surfaces typically found within refrigerators, dishwashers, and other kitchen appliances, condensation forms in locations where drainage systems were never designed to handle such volumes of water. This accumulated moisture creates ideal breeding conditions for mold and mildew growth, while simultaneously providing the electrolytic medium necessary for galvanic corrosion to occur between dissimilar metals within appliance components.

Vancouver’s notorious rainfall contributes to indoor humidity levels that frequently exceed the 30-50% range recommended for optimal appliance operation. During the peak rainy season, which extends from October through April, indoor relative humidity can climb above 60% even in well-ventilated homes. This elevated moisture content forces cooling appliances to work significantly harder to maintain proper temperatures, as the latent heat of vaporization required to condense excess water vapor represents a substantial additional load on compressor systems.

The temperature fluctuations characteristic of Vancouver’s climate create thermal stress cycles that are particularly damaging to appliance seals and gaskets. Unlike climates with more stable seasonal patterns, Vancouver experiences frequent transitions between near-freezing temperatures and mild conditions, sometimes within the span of a single day. These thermal cycling events cause repeated expansion and contraction of rubber seals, plastic components, and metal housings, leading to the development of micro-cracks and seal failures that compromise appliance integrity over time.

Research conducted by appliance repair specialists in the Vancouver area indicates that proper ventilation and humidity control measures can extend appliance lifespans by 3-5 years compared to unprotected units. This substantial improvement in longevity translates to significant economic benefits for homeowners, as the cost of implementing effective moisture control systems is typically far less than the expense of premature appliance replacement or frequent repair interventions. The unique challenges posed by Vancouver’s climate extend beyond simple moisture accumulation to include the complex interactions between humidity, temperature, and air circulation patterns within a typical residential environments.

The Science of Humidity Damage in Kitchen Equipment

Understanding the fundamental mechanisms through which humidity inflicts damage on kitchen appliances provides crucial insight for developing effective protection strategies. The damage processes operate at multiple levels simultaneously, from immediate electronic failures caused by moisture infiltration to long-term material degradation that gradually compromises structural integrity and operational reliability.

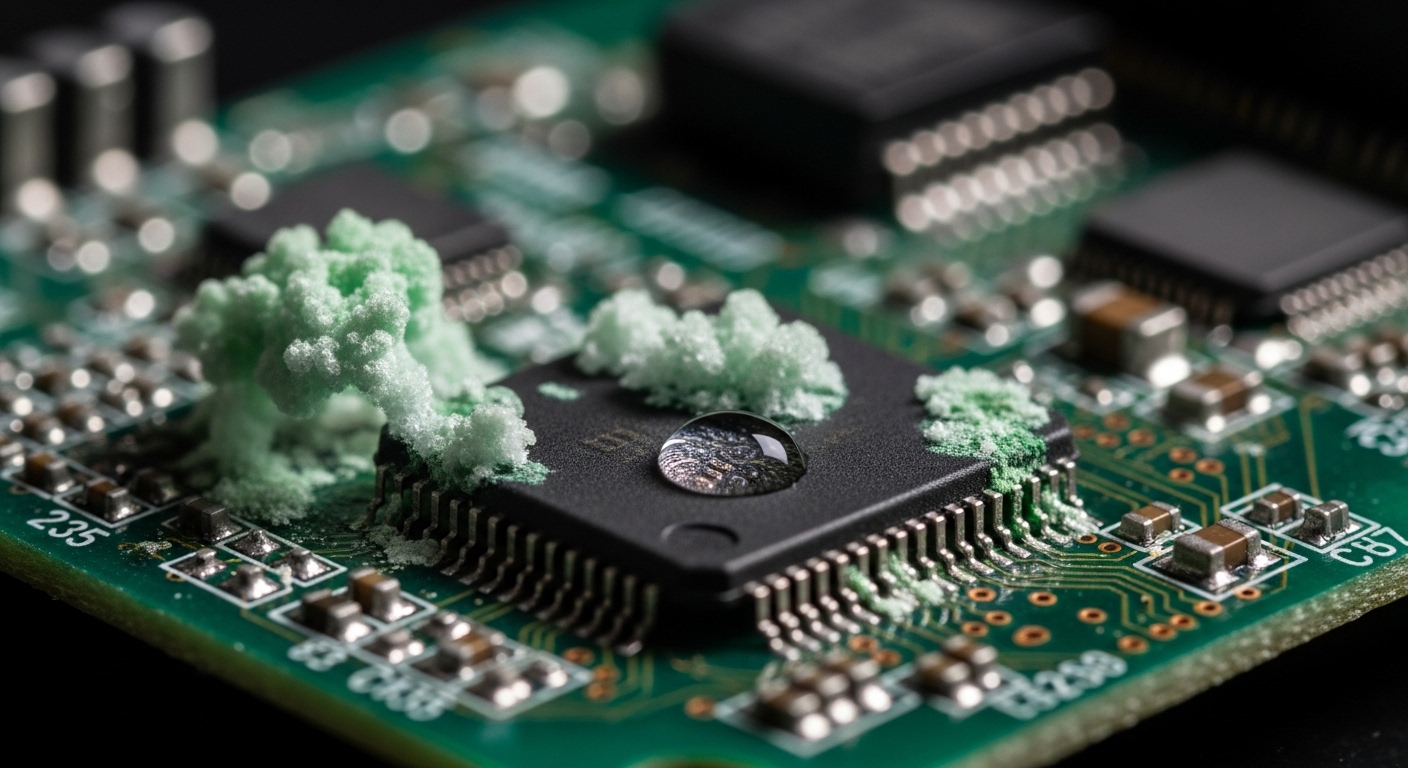

Electronic components throughout modern appliances are particularly vulnerable to humidity-induced failures due to their reliance on precise electrical characteristics that moisture can dramatically alter. When water vapor infiltrates control boards, sensor assemblies, and digital displays, it can cause immediate malfunctions through short-circuiting, or create long-term degradation through the promotion of electromigration processes that gradually move metallic ions within semiconductor junctions. The combination of Vancouver’s humidity with temperature changes creates expansion and contraction cycles that can crack solder joints and loosen connections over time, leading to intermittent failures that are notoriously difficult to diagnose and repair.

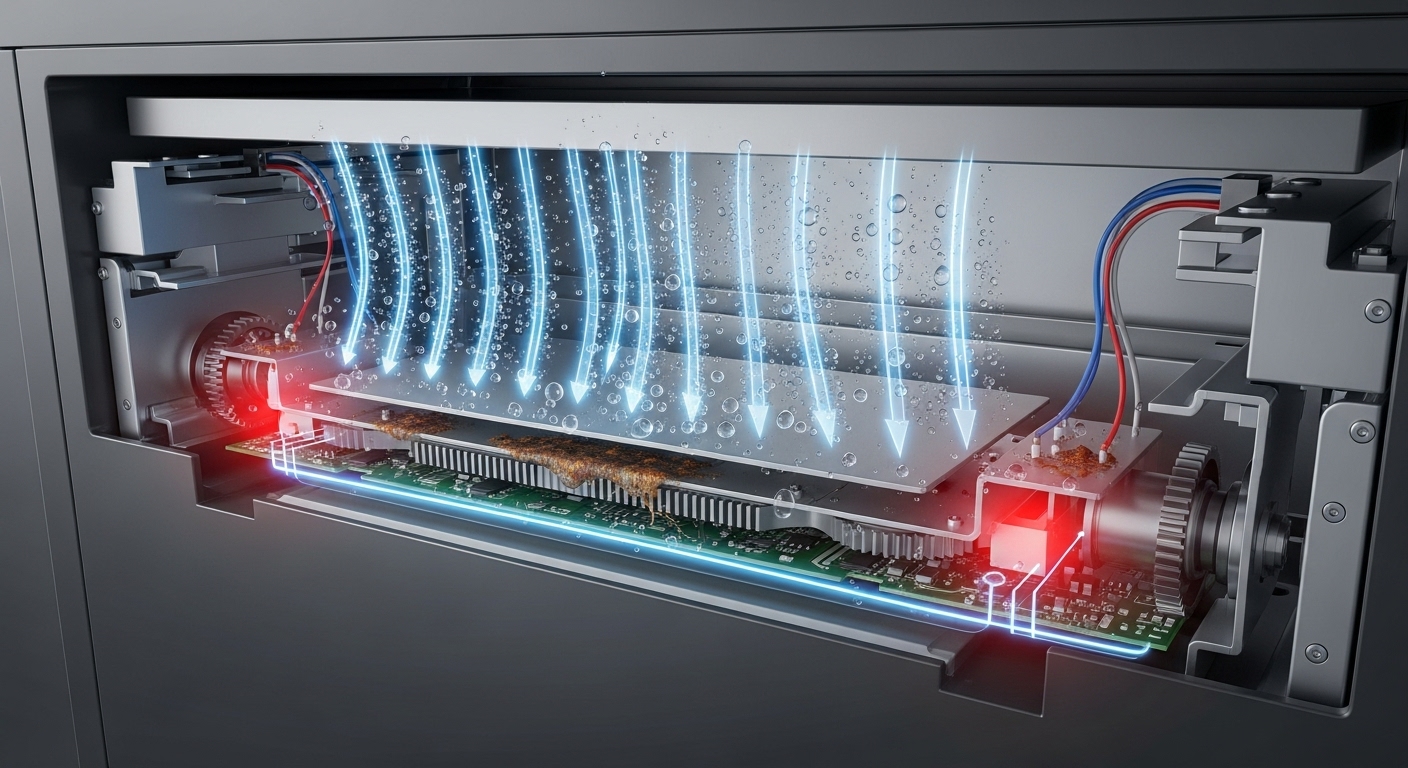

Refrigeration systems face unique challenges in humid environments due to the fundamental physics of heat transfer and moisture condensation. The evaporator coils that absorb heat from the interior compartments operate at temperatures below the dew point of ambient air, causing continuous condensation that must be properly drained to prevent ice formation and system damage. In Vancouver’s high-humidity environment, this condensation load can exceed the capacity of standard drainage systems, leading to ice buildup in unexpected locations and potential damage to refrigerant lines and compressor components.

The thermodynamics of moisture behavior within appliances reveals why humidity problems often manifest as seemingly unrelated performance issues. As moist air circulates through appliance cavities, it undergoes phase changes that release or absorb substantial amounts of latent heat energy. These thermal effects can disrupt the carefully calibrated temperature control systems that modern appliances rely upon, causing them to operate outside their designed parameters and experience accelerated component wear. This disruption becomes particularly problematic in precision systems where even small deviations from optimal operating conditions can trigger cascade failures throughout interconnected components.

Dishwashers represent a particularly complex case study in humidity-related appliance damage because they must manage both internal moisture from their cleaning operations and external humidity from the surrounding environment. The heating elements and drying systems in dishwashers work significantly harder in humid environments like Vancouver’s, as they must overcome not only the moisture from the wash cycle but also the elevated ambient humidity that prevents proper air drying. This additional workload shortens heating element lifespans and can lead to incomplete drying cycles that promote bacterial growth and unpleasant odors.

Salt Air Corrosion: The Invisible Threat

Vancouver’s proximity to the Pacific Ocean introduces a corrosive element into the local environment that extends far beyond the immediate waterfront areas. Salt particles carried by prevailing winds can travel surprising distances inland, gradually accumulating on and within household appliances where they initiate aggressive corrosion processes that dramatically reduce equipment lifespans. This salt air penetration occurs through normal ventilation systems and gradually builds up over time, making it an insidious threat that often goes unnoticed until major component failures